Because the core part of the LED luminaire is a PN junction (using different doping processes, the P-type semiconductor and the N-type semiconductor are fabricated on the same semiconductor substrate by diffusion, and a space charge region is formed at their interface, called PN. The light energy is converted into thermal energy by the absorption sheet inside the PN junction and the epoxy/silica gel. This heat has a huge side effect on the lamp, which makes the internal temperature of the LED lamp higher and higher, the brightness is lower and lower, and the life is higher. The shorter the coming, the better heat dissipation is the guarantee that the LED lamps will remain bright and extend their life.

Next, introduce the high-power LED package structure:

Because everyone's requirements for LED light source are getting higher and higher, in addition to different requirements for LED light extraction rate and light color, there are also different requirements for luminous intensity, etc. In order to meet customer needs and improve packaging process, then Each chip manufacturer has put forward higher requirements for the packaging factory, and designed a package structure that can better meet customer needs, thereby improving the light utilization efficiency of the LED external.

Different application fields put forward higher requirements for LED light sources. In addition to different requirements for LED light-emitting efficiency and light color, there are different requirements for light-emitting angle and light intensity distribution. This requires not only the upstream chip factory to develop new semiconductor materials, improve the chip fabrication process, design chips that meet the requirements, but also put forward higher requirements for downstream packaging plants, design a package structure that satisfies a certain light intensity distribution, and improve the light utilization outside the LED. rate.

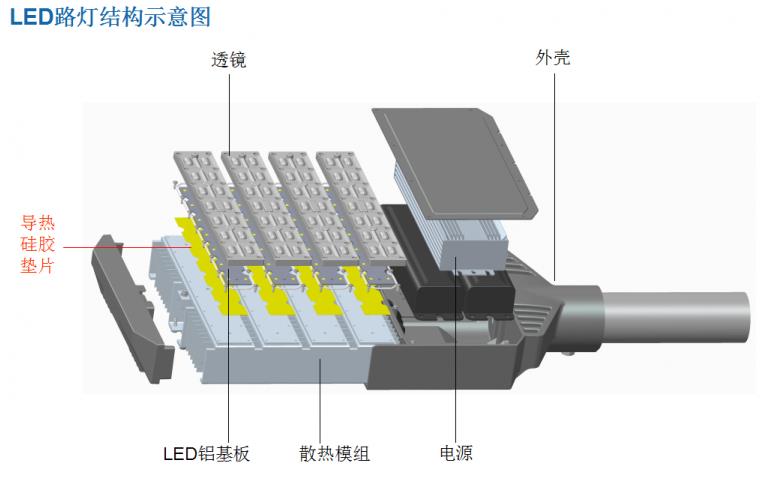

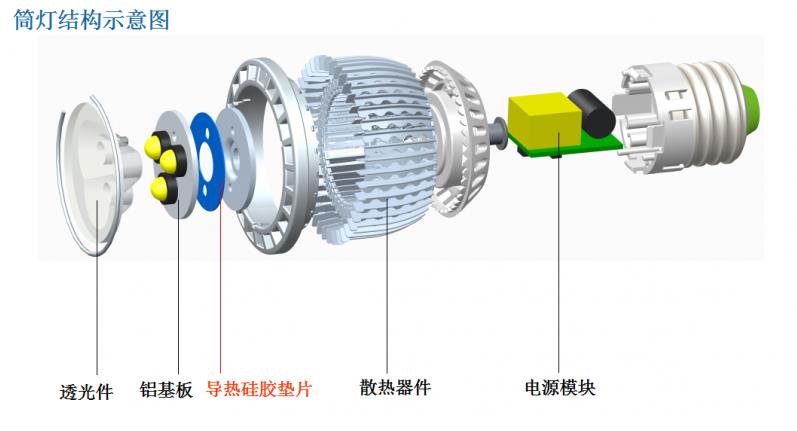

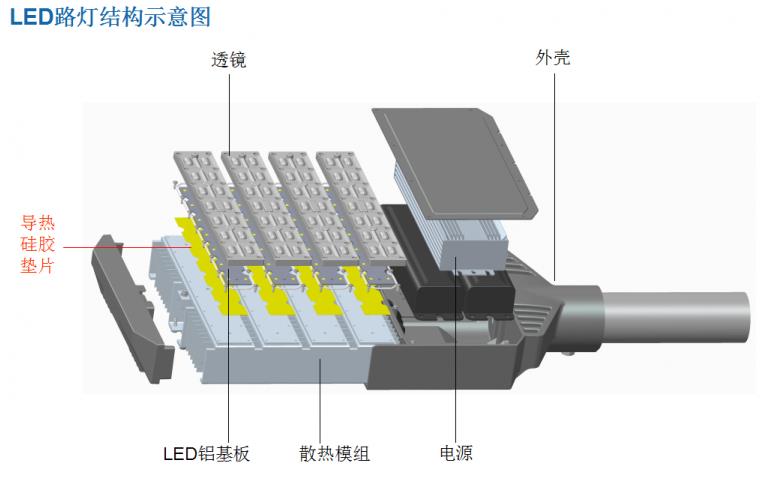

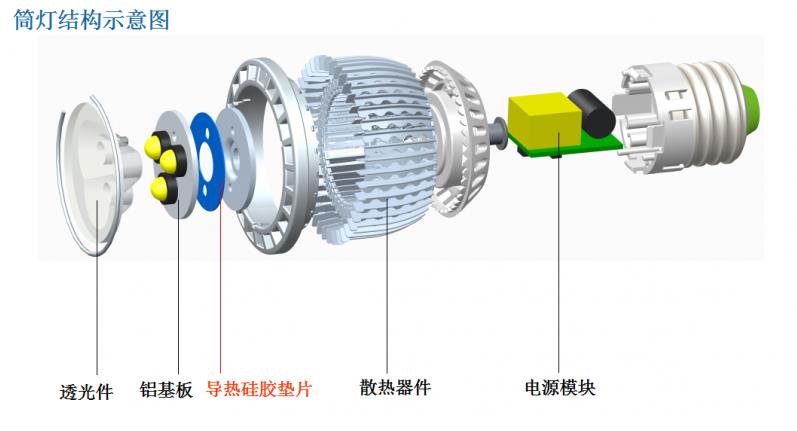

The existing heat dissipation technology consists of the following parts: heat-dissipating aluminum profile, thermal pads or thermal grease, thermal ceramic sheet, insulating iridium film LED lamp component, electrode, LED base, LED PN junction

The heat-dissipating process of the thermal silica gel is: the heat source from the PN junction of the LED passes through the LED base to the solder paste solder layer and then to the copper layer, through the insulating layer to the heat-dissipating aluminum plate to the thermal conductive pad or the thermal grease, and then The heat is transferred to the heat-dissipating aluminum plate, so that the entire heat-dissipation link is completed.

In general, the thermal conductivity of the base of the LED lamp is about 80W/mk; the thermal conductivity of the copper layer is 400W/mk, and the aluminum plate is about: 1w/mk, the thermal conductive silicone gasket of the LED lamp or the thermal grease. The thermal conductivity is generally 0.8~5.0W/mk, and the closer to the PN junction of the LED, the higher the heat flux density. Thus, the thermal conductive silica gel/thermal grease has the lateral thermal conductivity of the aluminum plate, and the heat flux density of the insulating layer is high. The heat flux density of the thermal grease, so that the most difficult heat dissipation is the insulation of the aluminum plate.

Since the most difficult heat dissipation is the insulating layer on the aluminum plate, the copper layer and the insulating layer are drilled and removed, so that the aluminum substrate can be exposed, zinc is deposited on the bare aluminum plate, and nickel is plated on the zinc surface. Then, copper is plated on the nickel, and then tin or gold is sprayed on the copper, so that the coating has strong adhesion and good heat conduction, and the LED is soldered to the aluminum plate after the plating process. After the welding is completed, the heat generated by the PN junction of the LED passes through the LED base to the solder paste soldering block and then to the aluminum plate and then passes through the LED lamp thermal conductive silicone gasket or thermal grease to conduct the heat to the heat dissipating aluminum profile and then dissipate in the air. After the insulation layer with very small thermal conductivity, the heat dissipation effect is greatly enhanced, and the temperature of the LED base is decreased, thereby prolonging the life and stability of the LED lamp.

Welcome to purchase Lian Tengda thermal conductive materials, the company's main: thermal silica film, thermal grease, thermal ceramic film, heat sink, thermal conductive film, factory independent production, quality control, credit guarantee